usp class vi compliant

AdvantaFlex TPE Biopharma Tubing. Excelon RNT 60 PVC Vinyl Lab Tubing.

Specially formulated for long term sealing.

. USP stands for US. Table 1 shows our standard programme FDA compliant com- FDA and USP class VI compliant. Pharmacopeia a private non-government organization that promotes the public health by establishing state-of-the-art standards to ensure the quality of medicines and other health care technologies.

Excelon RNT 1065 Vinyl Tubing. FEP Shrink Tubing 131 161. All these special grade products have passed this rigorous test.

For plastics they have six different classes based on duration and application. USP Class VI Testing Methods. Certificates of Analysis COAs report the test results for a specific batch of materials.

USP Class VI testing is conducted by producing an extract of the product with different extraction fluids such as polyethylene glycol and vegetable oil and injecting it in specimen rabbits and mice in vivo alive to observe the biological response to the extract. C-Flex ULTRA biopharma pump tubing. Class VI is the most stringent and requires.

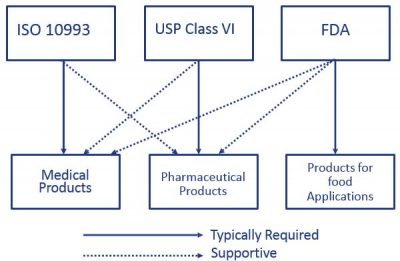

Compounds made without animal-derived ingredients BSETSE. Excelon RNT 68 Food Beverage Tubing. Both ISO 10993 and USP Class VI define testing requirements for biocompatibility the ability of a material to perform a desired function without causing adverse effects on the human body.

The thumb latch enables easy one-handed operation. Certified USP Class VI Silicones. USP Class VI Approved Plastic Materials.

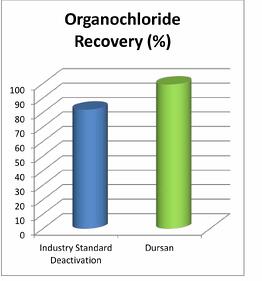

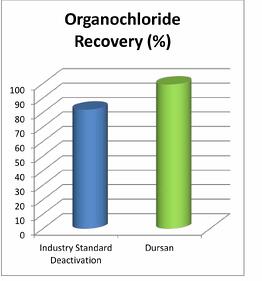

Enflo products are USP Class VI FDA ROHS REACH and Conflict Materials compliant. Dursan can be applied to more durable base materials like stainless steel to. Certificates of Conformance COC attest to a batchs.

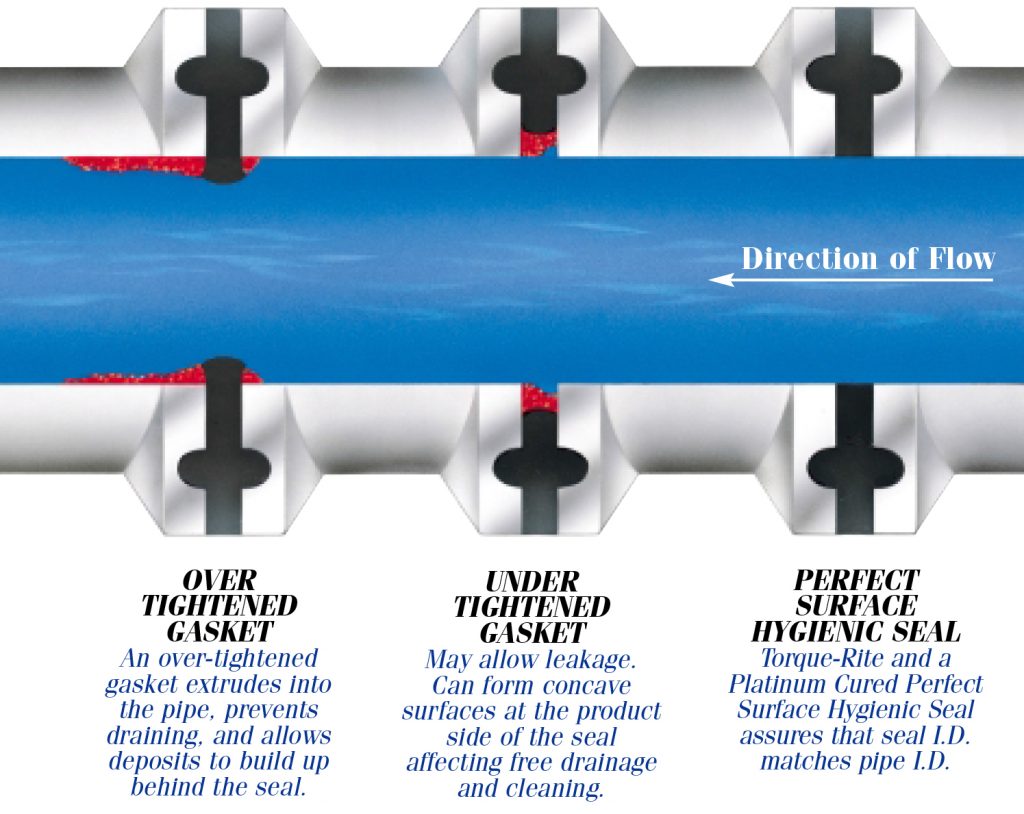

USP Class VI Compliant Materials for Medical and Pharmaceutical Products Meets USP Class VI requirements for use in medical and pharmaceutical applications. PPE manufactures medical and pharmaceutical grade gaskets and seals including O-rings sanitary gaskets and other high performance seals from a range of 15 USP Class VI compliant elastomers-. Many plastics manufacturers find it advantageous to have their materials classified especially if their plastic resins are a likely candidate to be used in medical devices.

United States Pharmacopeia USP 26 NF21 2003 Class VI. By ensuring that a material is non-toxic and wont result in immunological rejection biocompatibility testing ensures that a rubber is safe for use with. Typical applications for our FDA NSF 51 USDA materials are disposable medical devices surgical instruments and medical fluid dispensing components as well as a wide variety of food and beverage.

Master Bond systems are very versatile and can be used for both disposable and. ENFLON is a registered trademark for. ISO 90012015 Certified QMS.

SIMONA PP-H USP Class VI sheet is ideal for applications requiring biocompatibility testing standards defined by ISO 109931. Consumers implicitly rely upon the standards put into place by governing agencies to protect the publics health and well-being. The USP Class VI compounds must be made from ingredients with clear histories of biocompatibility that meet tighter requirements for leachates.

Sil 714002 USP class VI Silicone 1 70 Yes transl. One standard often overlooked but usually published alongside USP Class VI is FDA 21 CFR 1772600. Coatings like Dursan prevent protein binding and carryover in analytical systems and prevent system cross contamination while improving corrosion resistance and durability.

The result is a non-toxic bio-inert surface that is USP Class VI compliant. For most patient-contact applications a material that meets US Pharmacopeia USP Class VI andor ISO 109933 will be required. Sil 714001 USP class VI Silicone 1 70 Yes transl.

Specialty Silicone Products SSP provides complete certifications to demonstrate the quality of its SSP-2390 Series USP Class VI FDA and RoHS compliant silicones. Has a full range of specialty adhesives epoxies primers for polyolefins UV curables and silicones that have been fully tested to meet USP Class VI requirements. Most applications are fairly benign to elastomers.

The USP defines six plastics classes from class I to class VI with class VI being the most rigorous and most frequently requested certification. 24 materials which are compliant to FDA 21 CFR1772600. USP Class VI testing is conducted by producing an extract of the product with different extraction fluids such as polyethylene glycol and vegetable oil and injecting it in specimen rabbits and mice in vivo alive to observe the biological response to the extract.

When evaluating a new product many of our customers immediately jump to USP Class VI approval tests. An audible click is heard when the body and insert are coupled to confirm a secure leak-free connection. Moulded O-rings class 1 less than 10 furnace black These can be produced in all possible dimensions up to diameter 1400 mm internal.

These CPC quick-disconnect fittings feature an automatic shutoff valve which closes off the flow path at disconnection protecting valuable media while eliminating the need for pinch clamps. Testing is commonly done as per USP. Testing is commonly done as per USP which requires three types of.

Three chapters are applicable to elastomers plastics and polymeric materials.

What Is Usp Class Vi Testing Tbl Plastics

Why You Need Certified Usp Class Vi Silicones Specialty Silicone Products Inc

Standard Fda And Usp Class Vi Compliant Materials For All Types Of Hygienic Connections Repassa

Double Bagged Usp Class Vi Liquid Funnels

Standard Fda And Usp Class Vi Compliant Materials For All Types Of Hygienic Connections Repassa

Usp Class Vi Foster Corporation

Fda Usda Nsf51 Usp Class Vi Compliant Seals Products

Material Selection Medical Injection Molding Xcentric Mold

Iso 10993 Vs Usp Class Vi Medical Molding And Bicompatible Rubber The Rubber Group

Usp Class Vi What Is It And How Does It Apply To Elastomers Barnwell

Dursan Passes Usp Class Vi Testing Why Is That Important

Dursan Passes Usp Class Vi Testing Why Is That Important

Dursan Passes Usp Class Vi Testing Why Is That Important

1 25 1 1 4 Id Fda Usp Class Vi Platinum Silicone W Polyester Braid Food And Pharma Grade Flex Technologies Incorporated